The benefits of 3D printing have largely been underrated. In this article, we will explore the materials, processes, and legal regimes of this revolutionary technology. We’ll also take a closer look at the process of material extrusion. Ultimately, 3D printing will be beneficial to your business in a number of ways. Here are some of the most common examples:

Processes

There are many different processes of 3D printing, each with its own advantages and disadvantages. These processes vary in speed, cost, feedstock material, and geometric limitations. In addition to aesthetics, 3D printing also offers advantages and disadvantages in the field of engineering. This article explains three of the most popular techniques of 3D printing. Let’s get started! How 3D Printing Works

Inkjet printing uses a photosensitive material, which is then hardened by ultraviolet light. This process creates part after part, layer by layer. It can also use a variety of materials and is popular in the metal industry. These processes enable designers to create complex parts with high-dimensional accuracy and smooth surfaces. Listed below are some of the main 3D printing processes. Let’s take a look at each of these in more detail.

After the object is designed and created, manufacturing companies check the model file for any errors. A CAD package can identify errors and correct them before the final print is made. Several common errors include holes, self-intersections, faces, and manifold errors. After the model file is finished, the third step of 3D printing involves the printing of the object. Manufacturing companies upload an STL or AMF file to a 3D printer. The 3D printer uses the instructions included in the file to print the object.

Tolerances vary between processes, depending on the technology used, material used, and part design. Tolerances should be taken into account when designing a 3D part, especially for large production runs. Also, remember that 3D printing tolerances vary based on the technology used, so design guidelines are important to get better results. If you are not comfortable with these tolerances, consider outsourcing your 3D printing needs to someone else.

The process of 3D printing depends on the type of material used, the printing speed, and the type of material. Metal 3D printing is commonly done through Directed Energy Deposition (FDM) and is a popular technology in the rapid manufacturing and metal industries. These 3D printing technologies are usually attached to a multi-axis robotic arm, which moves back and forth. The nozzle then deposits metal powder or wire into the model’s surface layer-by-layer.

Material extrusion

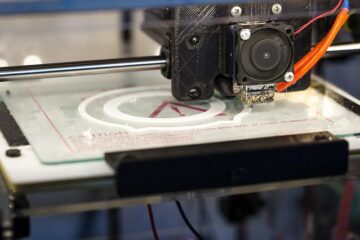

The process of material extrusion for 3D printing is called fused deposition modelling (FDM). It uses a heated nozzle to deposit a layer of material onto a surface. The platform moves up and down after each layer is printed. Many 3D printers use this process. FDM is the most common method for 3D printing, and it is a cost-effective way to create many different objects.

The materials used for material extrusion include wood flours, sawdust, barks, and lignocellulosic fillers. These materials are inexpensive and widely available, making them an ideal option for 3D printing hobbyists. Despite their shortcomings, material extrusion for 3D printing is a popular method for producing nonfunctional prototypes. It can also provide rapid prototyping for low-cost applications.

Researchers are currently exploring indirect applications for 3D printed wood and lignocellulosic composites. These materials are biocompatible and offer the potential to be used in tissue engineering and other applications. Further, researchers are working to find ways to commercialize these materials so they can use them in everyday products. Further, it is imperative to produce composite materials with properties equivalent to those of traditional materials. But in the meantime, there are promising signs for future applications.

A filament-based melt-extrusion 3D printer typically does not use screws in the heating barrels. Flow of melts depends on the modulus of the filament, the gravity of the material, and the force exerted by feeding gears. Polymers with low viscosity have a higher risk of developing problems with flow and deposition than others. Further, filaments with low viscosity can aggregate. To overcome this issue, researchers can use post-print thermal annealing.

Another extrusion-based process is bioprinting. Bioprinting utilizes aqueous suspensions of natural-derived biopolymers like nanocellulose. These hydrogels can be printed similar to thermoplastics, and have found applications in biomedical applications. They can also be used as reinforcements in 3D printers. This process has many advantages, but some challenges remain. In addition to plastics, bioprinting can be a more environmentally-friendly method of 3D printing.

Legal regimes

There are many legal regimes related to 3D printing. While 3D models can be freely distributed online, they can still be deemed a copyright infringement. The WIPO Copyright Treaty prohibits any circumvention of copyright measures, including by making copies of 3D prints. These protections include requiring copyrights holders to use technological methods, such as digitally tagging the files associated with the model. Rights holders may also wish to consider close collaboration with 3D printer manufacturers. Partnerships with online sharing platforms may also be useful in curbing unauthorized use of 3D prints.

These laws may seem inconsequential, but their application to 3D printing is closely related. These laws affect the design and enforceability of these new processes, and the decentralisation of production they enable. As a result, 3D printing allows individuals to produce items without the intervention of traditional gatekeepers. This means that laws are changing to match the new technologies. To this end, it is imperative to examine the impact of these legal regimes on the technology.

As 3D printing becomes more widely used, lawyers are grappling with liability issues. Defense counsel should consider exploring the possibility of arguing that the allegedly defective product was not a product. Further, it may be possible that the professional was not an authorized seller or manufacturer of the product. Other liability issues arise in connection with 3D printing, including issues regarding insurance coverage and contractual indemnity provisions. As the technology continues to grow and become more widely used, practitioners will continue to grapple with these legal issues.

For example, in France, it is prohibited to provide others with means of using an invention without authorisation. This means that 3D printers could create an impressive black market for cloned items. As such, 3D printers may lead to a number of copyright issues for both companies and the consumer. There are also legal considerations regarding IP protection and the rights of artists. This article has been written by DLA Piper lawyers.

Benefits

The advantages of 3D printing go beyond aesthetics. It reduces the costs of stocking and printing in bulk. Rather than storing and repairing large inventories, 3D printers can create parts on demand. They can be assembled, shipped, and sold as they are needed, which means fewer resources are wasted and less money is spent. Additionally, 3D printers enable designers to test new ideas quickly, which can lead to better designs.

Because 3D printers are able to produce products from start to finish, manufacturing time is drastically shortened. The cost of shipping and transportation is also eliminated, as printed parts can be made within hours. Companies can scale up production output by adding multiple machines. This can help them maintain a competitive edge while decreasing their product cycle times. The following are some of the other benefits of 3D printing. The technology is gaining widespread adoption, and benefits are being realized worldwide.

It reduces the time required for prototyping. Because 3D printers are fast and cost-effective, businesses can create and test new products faster and cheaper than ever before. The technology also enables clients to create life-size prototypes, which is one of the most important benefits of 3D printing. Once you’ve developed your prototype, you can refine it further based on feedback and your own preferences. This means faster time to market for your new product.

Besides the benefits of reduced waste and cost, 3D printers are more environmentally friendly. It is possible to use recyclable or organic plant-based materials in 3D printing. In addition, it reduces the amount of materials used in conventional construction. In some industries, light weighting is an important feature. This can lead to greater fuel efficiency, which is great for the environment. Lastly, 3D printing makes it easier to build complex structures with very little human effort.

In the aerospace industry, aerospace companies are always on the lookout for new ways to reduce weight in airplanes. Every ounce saved means more cargo and passengers. Furthermore, reducing weight increases strength, and complex matrix designs make it difficult to manufacture. 3D printing solves this problem and enables manufacturers to create complicated parts without compromising on aesthetics. Further, the benefits of 3D printing extend beyond aesthetics. For example, aerospace companies use 3D printers to test new parts and improve existing products.

0 Comments